Cold Roll Forming

What can you do with cold roll forming?

• Very narrow tolerances, from ± 0.05 mm.

• Ability to form closed shapes by in-line welding.

• Ability to form materials with polished and pre-painted surfaces.

• Profiles with a thickness of 0.3 to 2 mm and a width of up to 200 mm.

• In-line machining such as punching, cutting, rolling and trimming to length.

• Suitable for ferrous, non-ferrous, stainless steel and other deformable metals.

Why Use Cold Roll Forming?

• Ensures a high degree of consistency and accuracy.

• Provides effective solutions to complex challenges.

• Enables customised product design and production.

• It is ideal for constant profile parts with long lengths and large volumes.

• Is suitable for a wide range of metals, such as stainless steel, aluminium and prepainted steel.

The Cold Rolling Process

Collaboration For Complex Metal Profiles

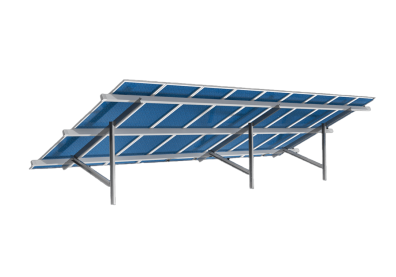

Your project requirements are assessed by our team of 50 full-time engineers and technicians within Strolar Mounting Systems. They will work as an extension of your in-house designers to translate your complex requirements into highly effective, quality solutions. As specialists in research and product development, design, manufacturing, and technical support for tooling and machinery, we use the latest developments in computer simulation technology, advanced engineering hardware, and the expertise of our in-house team. Shapes by in-line welding.