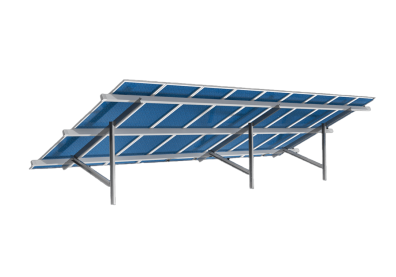

Looking for the Best Solar Mounting Structures Company in India?

24/09/2024

Strolar’s Global Achievement: 4 Solar Projects in 4 Countries in 1 Month

11/10/2024New Hot-Dip Galvanizing Plant in Kosi Kalan : A Game-Changer

We are thrilled to announce the launch of our new state-of-the-art Hot-Dip Galvanizing (HDG) plant in the UPSIDC Industrial Area, Kosi Kalan, Uttar Pradesh. This facility is a testament to our ongoing commitment to quality, innovation, and sustainability in the steel industry. With this new plant, we aim to set new benchmarks in providing world-class corrosion protection solutions to industries like renewable energy, infrastructure, and telecom.

Why Hot-Dip Galvanizing Matters

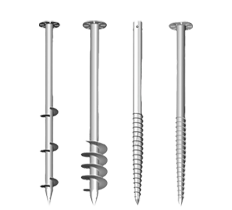

Hot-Dip Galvanizing is a specialized process that involves immersing steel components in a bath of molten zinc. This creates a robust, highly durable coating that provides exceptional resistance to rust and corrosion. Steel treated through HDG can last up to 50 years or more, even in the most challenging environments. This process not only extends the lifespan of steel structures but also minimizes maintenance and replacement costs, making it a preferred choice for long-term projects.

Key benefits of Hot-Dip Galvanizing include:

Exceptional Corrosion Resistance: The zinc coating acts as a sacrificial layer, protecting the underlying steel from moisture and chemicals that cause corrosion.

Enhanced Structural Integrity: By preventing rust, HDG maintains the structural strength of steel components over time.

Low Maintenance Costs: Galvanized steel requires little to no maintenance, resulting in significant cost savings over its lifecycle.

Sustainability and Eco-Friendliness: Hot-Dip Galvanizing is an environmentally friendly process, as zinc is 100% recyclable and does not degrade over multiple uses.

What Sets Our HDG Plant Apart

Our new HDG facility in Kosi Kalan is equipped with cutting-edge technology to ensure precision, quality, and efficiency at every stage of the galvanizing process. The plant features a high-capacity zinc kettle capable of accommodating large steel components and a fully automated material handling system that ensures consistent and uniform coating on each product.

Advanced Features and Capabilities:

Large Zinc Kettle: Our facility includes a spacious zinc kettle that enables the galvanization of steel components of various sizes and shapes, from small parts to large beams and columns.

High-Precision Temperature Control: We use advanced temperature management systems to maintain the optimal conditions for zinc adhesion, ensuring uniform and flawless coatings.

Efficient Process Flow: The entire galvanizing process, from pre-treatment to cooling, is streamlined to minimize lead times and maximize throughput.

Custom Solutions: Whether you require galvanization for standard steel products or specialized components, our team can tailor the process to meet your specific project requirements.

Environmentally Conscious Operations: Our facility adheres to stringent environmental standards, employing energy-efficient technologies and responsible waste management practices to reduce our ecological footprint.

With these features, we aim to deliver a superior galvanizing experience that guarantees long-lasting protection and peace of mind for our clients.

Meeting the Needs of Diverse Industries

Our new HDG plant caters to a wide range of industries, ensuring that each project benefits from the highest quality galvanizing solutions. Key sectors we serve include:

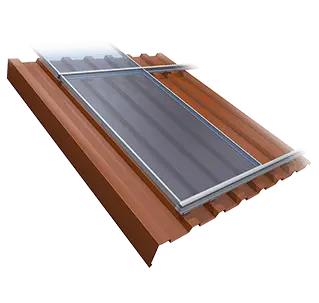

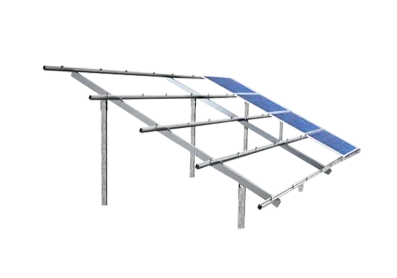

Renewable Energy – Solar Mounting Structures: As a key supplier of solar mounting solutions, our HDG plant is instrumental in ensuring that solar structures remain resilient and corrosion-free, even in harsh outdoor environments.

Telecom Industry: From communication towers to support structures, our galvanizing services extend the lifespan of telecom components, enhancing safety and reducing the need for frequent maintenance.

Infrastructure Development: Bridges, highways, and other critical infrastructure projects depend on galvanized steel for its strength and durability, making it an ideal choice for long-term investments.

Strategic Location for Optimal Reach and Connectivity

Our Kosi Kalan plant is strategically located in the UPSIDC Industrial Area, providing excellent connectivity to major cities and industrial hubs across Uttar Pradesh and Northern India. This location allows us to serve clients more efficiently and ensures faster delivery times for large-scale projects. With easy access to key transportation routes, we are well-positioned to support both domestic and international projects.

The strategic positioning of this plant not only reduces logistics costs but also enables us to respond quickly to urgent project requirements, ensuring that our clients receive their galvanized products on time, every time.

A Commitment to Quality, Innovation, and Customer Satisfaction

Our newly launched HDG plant stands as a testament to our commitment to excellence. Every aspect of our operation is designed to maintain the highest standards of quality, from raw material selection to final inspection. We have implemented a rigorous quality control process that includes:

In-Depth Pre-Treatment Analysis: Before galvanization, all components undergo thorough cleaning and inspection to ensure that they are free from impurities, ensuring a perfect bond between steel and zinc.

Stringent Quality Assurance: Each batch is carefully monitored to maintain consistency and compliance with international standards, ensuring that every product meets the performance expectations of our clients.

Post-Galvanizing Inspection: After galvanizing, every component is inspected for coating thickness, adherence, and uniformity, guaranteeing a flawless finish.

Paving the Way for Future Growth

The launch of our new HDG plant is just the beginning. This facility is part of a broader strategy to expand our capabilities and reinforce our position as a leader in the steel industry. As we continue to invest in new technologies and innovative processes, our goal is to create a network of galvanizing facilities that can meet the growing demand for high-quality corrosion protection solutions across India and beyond.

In the coming months, we plan to introduce additional services, including powder coating and duplex coatings, to offer even more versatile and customized solutions to our clients.

Partner With Us for Reliable and Durable Solutions

Our new HDG plant enables us to deliver best-in-class corrosion protection for your steel products, ensuring long-term reliability and reduced maintenance costs. If you’re looking for high-quality galvanizing solutions for your projects, our team of experts is ready to help.

Whether it’s for solar mounting structures, telecom towers, or large-scale infrastructure, our HDG plant in Kosi Kalan is equipped to handle all your needs with precision, efficiency, and a commitment to excellence.

Feel free to reach out to our team to discuss how our advanced HDG solutions can benefit your next project!