Strolar

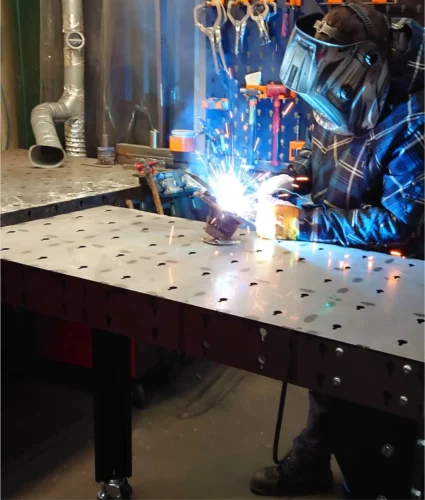

Welding

We perform both manual and robotic welding and have experience with complex weldments. All our welders are trained, tested, and certified to perform at a level that meets or exceeds the applicable welding codes for the industries. Along with robotic welding, we also offer manual welding including gas metal arc welding, pulse gas metal arc welding, gas tungsten arc welding, tungsten inert gas welding, soldering and brazing. To insure the integrity of your parts, we have a full-time aws certified welding inspector and to ensure unparalleled strength and longevity we perform non-destructive testing on all welds.

Forming Equipment

Two (2) ABB IRB 2600 Six Axis Robots

• Welding in coordination on the same part

• Part touch sensing

• Part seam tracking

• Quick Neck Changing Station

• Torch Cleaner Service Center

• Two (2) Lincoln Welding Power Supplies

Three (3) ABB Welding Robots

• Part touch sensing

• Part seam tracking

• Load capacity: 1,650 lbs.

• 57" max swing diameter

• Supports synergic MIG (GMAW) and pulsed MIG (GMAW-P)

• Fully coordinated motion between robot and manipulator

• Six Axis ABB robot two station interchanging manipulator w/two servo axis per side (five total servo axis)

ABB 5000K Sky Hook

• Pre-Heat and temperature sensing

• Six axis ABB robot with tool changer

• Part touch sensing and seam tracking

• Load capacity 11,000 lbs and 100" x 142"

• Full coordinated motion between robot and sky hook positioner

Manual Welding and Positioners

Production Welding (Mild Steel, Stainless Steel & Aluminum)

• Weld Positioners

• Soldering and Brazing

• (TIG) Tungsten Inert Gas

• (GMAW) Gas Metal Arc Welding

• (FCAW) Flux Cored Arc Welding

• (GTAW) Gas Tungsten Arc Welding

• Various capacities (max 20,000 lbs.)

• (GMAW-P) Gas Metal Arc Welding (Pulse)

Integrated Manufacturing Cell

• True 4th axis

• Two 630mm pallets

• 40hp spindle motor

• Part touch sensing

• Part seam tracking

• 57" max swing diameter

• Load capacity: 1,000 lbs.

• Work surfaces: 24.8" x 24.8"

• Fanuc controls

Six Axis ABB robot

• 60-station automatic tool changer

• Load Capacity: 2,640 lbs per pallet

• Axis travels: x = 39.37", y = 31.50", z = 33.46"

• 6,000 RPM spindle with high pressure coolant

• Supports synergic MIG (GMAW) and pulsed MIG (GMAW-P)

• Fully coordinated motion between robot and manipulator

• Two station interchanging manipulator w/two servo axis per side (five total servo axis)

Get in Touch

Use our contact form to easily reach out to us. Fill in your details we'll respond promptly. Connect with us hassle-free and start a conversation today!